ICMSE-MGI Digital Data Workshop

Contents

Digital Data for MGI: understanding requirements and investigating semantic and federated approaches

Background

"Integrated Computational Materials Engineering (ICME) is the integration of materials information, captured in computational tools, with engineering product performance analysis and manufacturing process simulation." his definition of ICME provided by the National Research Council in 2008 describes the complexity of the engineering framework being constructed to enable 21st century materials science and engineering. This framework will be comprised of modeling tools and experimental data to provide an integrated engineering capability that describes the composition, processing, structure, and property relationships of a material used to design and manufacture components.

The ICME construct is very much in keeping with the goal of the Materials Genome Initiative’s (MGI) to double the speed at which we discover, develop and manufacture new materials. The goal will be achieved through the development of a materials innovation infrastructure that includes computational tools, experimental tools, digital data, and collaborative networks.

Workshop Purpose

Numerous entities have observed that the complexity and significantly enhanced engineering capability of an ICME framework raise important questions pertaining to the ability to discover, assess, integrate and use materials data and information. This workshop will focus on the application of semantic technologies to structural design <ref>Discussion should also include functional material considerations (e.g. thermal conductivity, lightning strike, etc.)</ref>, manufacturing, and materials design and development.

- Facilitate cross-talk between approximately thirty technical subject matter experts (SME): structural design, materials & manufacturing, data modeling, and knowledge discovery

- Explain and demonstrate how federated architectures enabling linked data and knowledge representation designed for the semantic web can be applied to the ICMSE domain

- Identify general provenance requirements and present approaches to capture provenance

- Discuss the SOA in ensuring data integrity and security

Target Audience

Those who create and use data:

- Structural Designers

- Materials Suppliers

- Materials Scientists and Engineers

- Supply chain managers

- Manufacturing Engineers

Those who create technologies to create federated data architectures and capture knowledge:

- Information ontologists

- Knowledge capture and dicovery experts

- Data modelers

- Security experts

Location and Schedule

The specifics of this schedule are draft. The agenda will be finalized after receiving feedback from attendees. The workshop will be held at Kno.e.sis Center - some interesting facts about Kno.e.sis can be found at this link.

Wright State University

377 Joshi Research Center, 3640 Colonel Glenn Highway,

Dayton, OH 45435, USA

13-14 November 2013

| Start Time | Duration | Title | Speaker | Organization |

| 13 November 2013 | ||||

| 8:30 AM | 0:10 | Welcome and Introductory Comments | Amit Sheth | Kno.esis |

| 8:40 AM | 0:10 | Workshop Impetus and Objectives | Clare Paul | AFRL/RXT |

| 8:50 AM | 0:20 | Compositionally Complex Alloys: Information-Driven Discovery and Design | Dan Miracle | AFRL/RX |

| 9:10 AM | 0:20 | High-fidelity Multi-disciplinary Design of Aerospace Vehicles | Ray Kolonay | AFRL/RQVC |

| Semantic technologies used by other domains (semantic annotation, indexing, faceted search, etc.) | ||||

| 9:45 am | Break | |||

| 10:00 am | Current efforts to enhance seamless materials data exchange between machines (e.g. CEN) | |||

| Data: If I find it, can I trust it? | ||||

| Data: Can I protect it? | ||||

| Breakout session vignette | ||||

| 11:30 am | Lunch | |||

| 1:30 pm | Break into sessions | |||

| 4:30 pm | Open discussion and end-of-day wrap-up | |||

| 14 November 2013 | ||

| 8:30 am | Review of the morning’s objectives | |

| 8:45 am | Break into sessions | |

| 11:45 am | Lunch | |

| Reconvene for session reports | ||

| Materials Development & Design report | ||

| Manufacturing report | ||

| Structural Design report | ||

| 1:15 pm | Open discussion & workshop wrap-up | |

| 2:00 pm | Formal conclusion of the workshop | |

| 2:30 pm | Ad hoc discussion for workshop participants wanting to continue the dialog | |

A Conceptual Framework

To help strike a balance between participant discussion becoming overly abstract or too concrete, the concept of a product-process-product (P3-triplet) is introduced for use during the workshop.

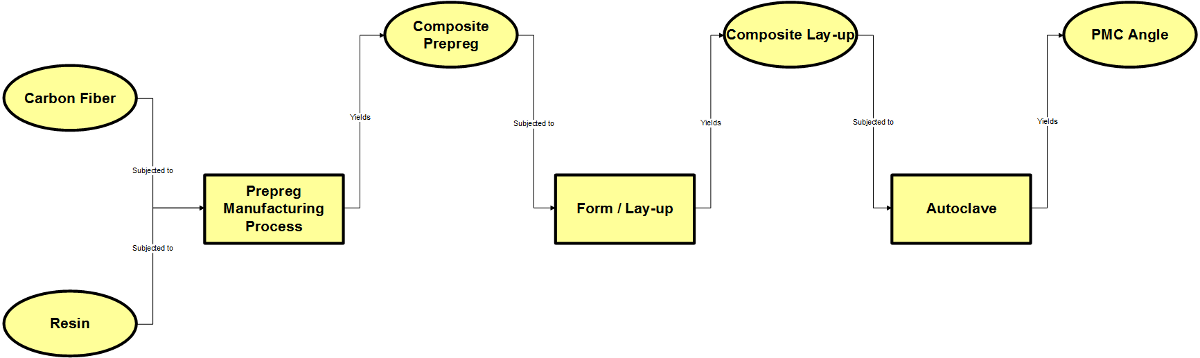

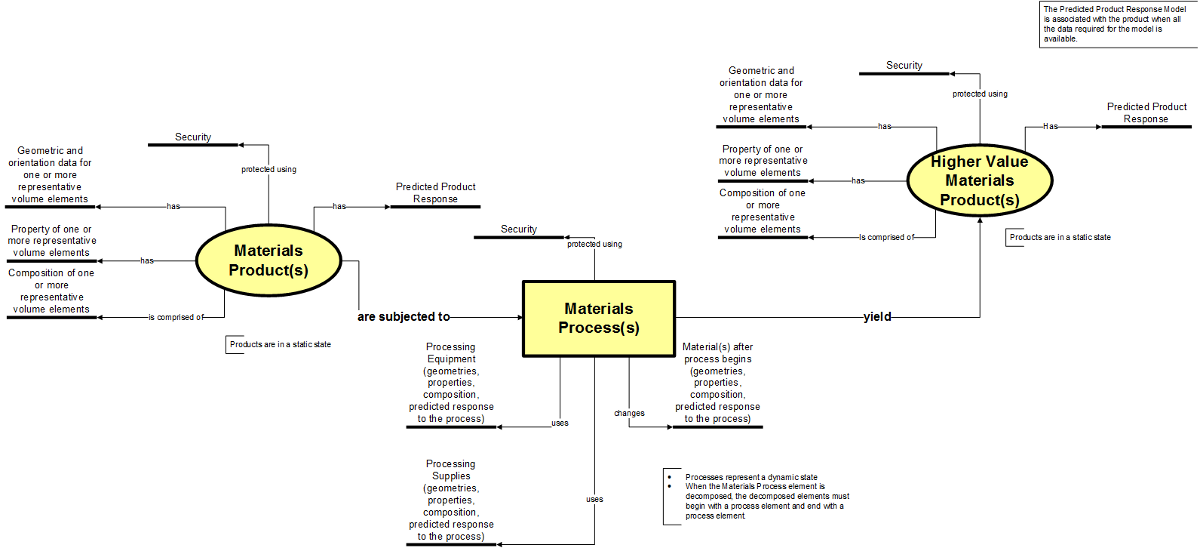

Triplets represent materials or products subjected to a process (M&P, manufacturing, fabrication, assembly) yielding higher value materials or products. For example, an un-cured composite lay-up is subjected to an autoclave process to yield a consolidated composite. Another example would be a composite panel being subjected to a trimming and hole drilling process to yield a panel ready for assembly with other parts of an aircraft.

At various points along the continuum from raw material to finished product, virtual products are created as part of the design process. Modeling and simulation (M&S) of elements within each triplet are used to predict the response of a product or process. For example, chemorheology models are used to help predict resin flow during the cure process, and discrete damage models are used predict failure modes and strength in composites.

Triplets "collect" data about the virtual and physical products and processes and provide a convenient way to decompose the system into workable elements.

An example of a triplet from the simple diagram shown below in Fig.1 would be an un-cured composite lay-up subjected to an autoclave process to yield a PMC angle. In reality, a tip-to-tail P3-triplets network associated with a material or product could consist of tens, hundreds or thousands of P3-triplets.

Note, however, that P3-triplets are not intended to be the only possible framework to help model the system. The primary intent is to establish context and a framework during the workshop.

Breakout Sessions

Breakout sessions will bring SMEs from the semantic/knowledge domain together with SMEs from the materials, manufacturing, and design domains. The use cases will be the common thread as attendees endeavor to explore how semantic technologies can be used to (1) link and discover data from disparate sources (federated architecture), and (2) capture, understand and discover relationships between concepts (parameters, phenomena, facts, experiences). Additional discussion will focus on understanding the history of the discovered data (part of provenance), determining its quality and assessing if it can be trusted. And finally, discussion should include the topic of security risks and mitigation approaches: data integrity, software agent authentication and access control, secure data transfer, and current threats facing world-wide-web-connected computers.

Prior to the Workshop

- Those with a materials or design background should read Linked Data - The Story So Far <ref> Bizer, Christian, Tom Heath, and Tim Berners-Lee. "Linked data-the story so far." International Journal on Semantic Web and Information Systems (IJSWIS) 5.3 (2009): 1-22. </ref>

- Those with a computer science / information background should read Chapter 1 – Materials for Engineering from the University of Tennessee.

- Attendees will provide use case descriptions: (1) materials design and development, (2) manufacturing, and (3) structural design. Once received, the individual use cases may be combined with other use cases to create a total of three (one for each breakout session).

- Attendees will associate a series of P3-triplets with their respective use case.

- Example use cases

- Find high quality processing data about the forging of steel; include both open and access controlled data (assume “NDA” between materials supplier and manufacturing engineer/company). Automatically mash the data together.

- Find all factors that contribute to the development of porosity in composites.

- Extend someone else’s research on a toughened resin without having to rerun any of their experiments. Run updated M&S tools on previously generated data as well as data from new experiments that used a modified resin.

- Scan the web to find materials that meet a specific combination of performance criteria (e.g., thermal conductivity, strength, fatigue resistance)

- Questions to keep in mind while your team is defining requirements/solutions based on the use case:

- Does this system fail if process or product information is tightly held?

- What provenance metadata is required to ensure trust?

- What’s a scalable way to enable shared, but controlled, access? Policy-based access?

- What are some of the authentication options? Is one better than the others?

- What’s needed to create a shared vocabulary (e.g., common definition for the term "strain to failure")? Is it even possible?

- What are some of the more important relationships between parameters, phenomena, facts, or experiences (e.g. vacuum bagging reduces gas infusion, gas infusion creates porosity, porosity reduces strength)

- Will semantic technologies work for really large data sets?

- Can linked data be used to capture data values (structured data) as well as files (e.g. pdf or images)?

Contact

For more information:

Tonya Davis

tonya@knoesis.org

937-775-5217

<references/>